How are LED screens produced?

Published:2023-12-21Views:548

LED screen is an important product of the development of modern science and technology. It has the characteristics of high brightness, high contrast, and high color reproduction. It is widely used in various display occasions, such as billboards, stage backgrounds, monitoring centers, etc. So, how are LED screens produced? Let’s take a closer look below.

1. Chip preparation

The core component of the LED screen is the LED chip, which is the luminous part of the LED lamp bead. During the chip preparation process, the wafer material is first cut into small pieces, and then metal and semiconductor materials are deposited on the wafer through chemical reactions and deposition techniques.

Next, micron-level photolithography and etching are performed through mask technology to form conductive and light-emitting areas in the chip. Finally, cleaning and testing are performed to ensure that the chip quality meets the requirements.

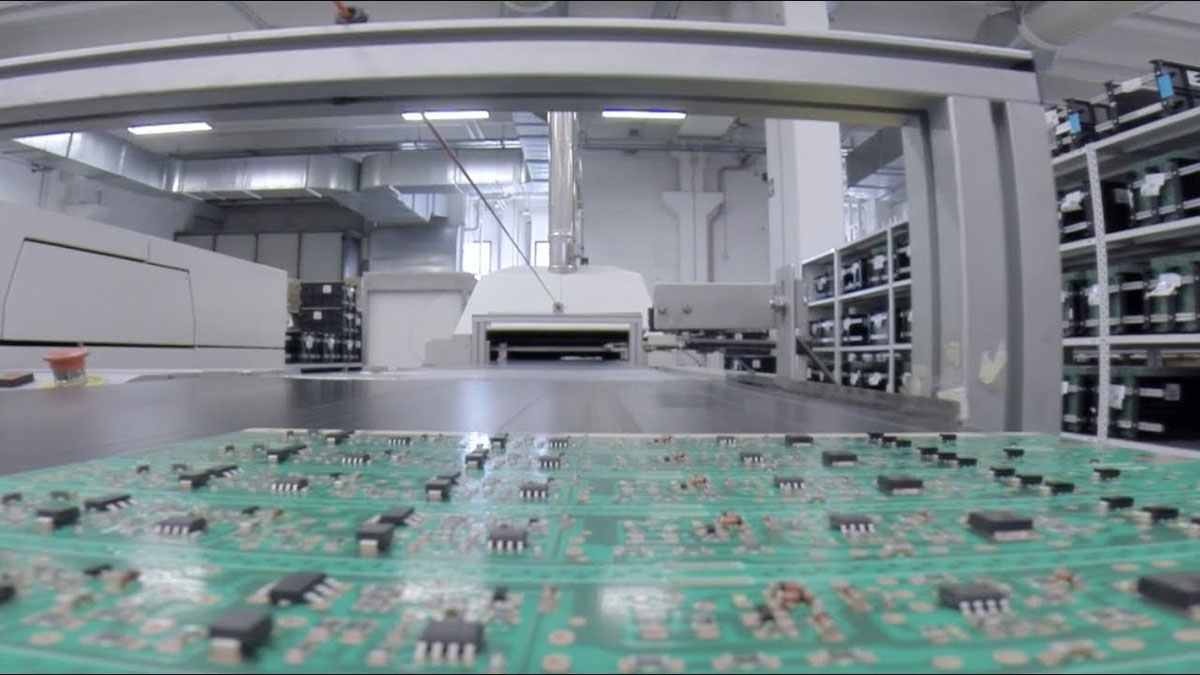

2. SMT process

Paste the prepared LED chip on the light strip of the PCB board to form pixels. During this process, pay attention to the aspect of the lamp, do not stick it backwards, and do not stick it less. At the same time, it is necessary to ensure that the distance and position between each lamp bead is accurate to ensure the clarity and brightness of the screen.

3. Solder inspection

Check the patch on the light board to see if there are any lights falling off or weak soldering. If there is a problem, it needs to be repaired and adjusted in time.

4. Installation of box frame

Align the finished light panel and cabinet frame, and tighten the screws. This step is to fix the LED screens together to form a complete display unit.

The driver board is the control system of the LED screen. It is responsible for receiving input signals and controlling the on and off of the LED lamp beads. During the production process of the driver board, steps such as chip placement, driver cable connector, power connector welding, capacitor welding, and driver IC welding are performed in sequence. Finally, an aging test is performed to ensure that the driver board is stable and reliable.

6. QC testing

After the LED screen production is completed, quality inspection is required. This step includes lighting the aging test for 72 hours, including 48 hours of red, white, blue, and green light, used to check for weak soldering or necrotic lamp beads for repair and replacement.

Play the video content for another 24 hours. If any color cast or brightness inconsistency is found, balance adjustments will be made. Before shipment, ensure that the LED display screen appears perfectly and operates stably.

7. Module assembly and debugging

The module is the basic unit of the LED screen, which consists of multiple lamp beads and drive circuits. After the module assembly is completed, debugging work needs to be performed.

Through circuit connections and software settings, ensure that the module works properly and can receive input signals and display images correctly. At the same time, it is necessary to ensure that the connection between each module is stable and reliable to ensure the normal operation of the entire LED screen.

8. Screen production and assembly

Finally, the screen body is produced and assembled. The screen body is a display unit formed by assembling multiple modules together. It has the functions of protection, support and beauty. During the production process of the screen, factors such as the size, shape, structure and materials of the screen need to be taken into consideration.

At the same time, it is necessary to ensure that the connection between the screen body and the module is stable and reliable to ensure the normal operation and service life of the entire LED screen.

The above is the production process of LED screens. From chip preparation to screen production and assembly, every step requires strict quality control and technical support. Only through strict production processes and quality inspections can high-quality LED screens be produced.

.png)